JOS does not employ additional short term staff to increase our short term capacity and therefore will only tender for jobs within our scope this enables us to maintain our high standards.

We understand that our employees are our most important and valuable asset. Our philosophy is to train our staff to the highest level enabling them to leave JOS and at the same time providing them with terms and conditions so they don’t want to leave. This philosophy has enabled us retain our team maximising efficiencies and ensures our clients always get a first class job.

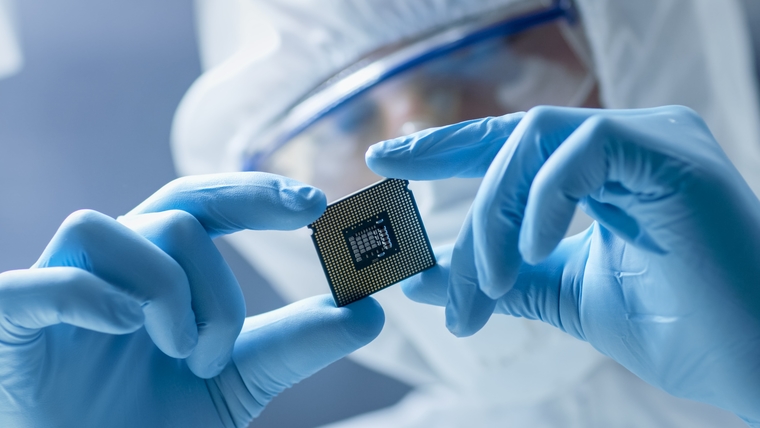

Many industries such as pharmaceuticals, biotechnology and semiconductor manufacturing rely on encompassing their entire manufacturing facilities with in a sterile environment. During construction and operation of the facility the clean room partitions are sometimes damaged and Must be renewed or repaired to ensure the environment is contamination free.

Control of microorganisms and airborne particles within the clean room facility is critical to the quality of its end product. Very slight scratches, dents or drill holes may hinder this control process rendering the best cleaning practices useless. Depending on the level of damage most damage can be repaired on site.

Repairing the panels is far quicker and cost effective in comparison to removing the entire panel. Repairing the panel in situ also minimises the risk of exposing the controlled environment to dust, microorganisms and other contaminants that may be released during the removal and renewal process of the panels.